News

The general attentions about making laser etch silicone keypad

2019-07-13 14:31:34 Clicks:

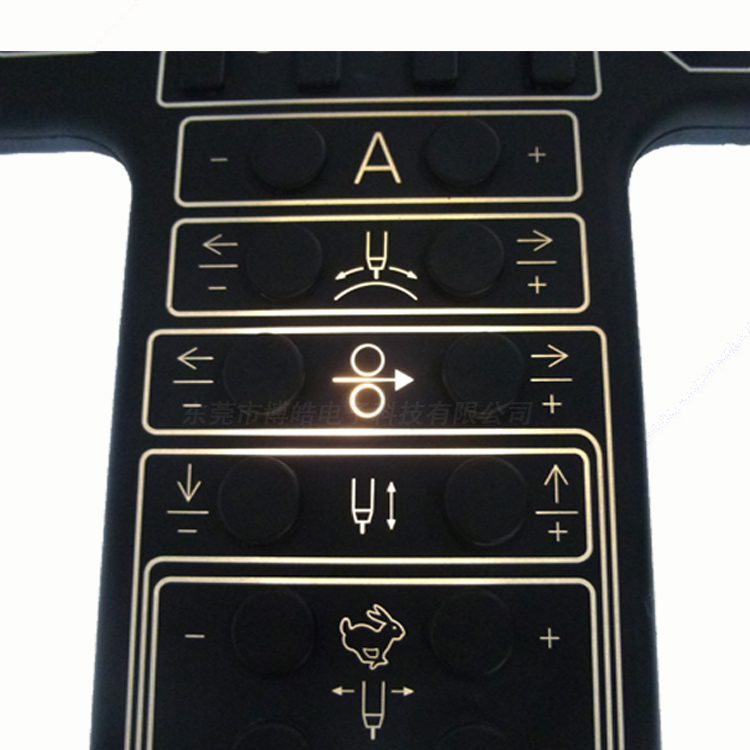

Laser etching is a common technology of customizing silicone keypads. Many people pay attentions to make laser etch silicone keypad. The purpose is to make the key patterns have the light penetrating ability, so the laser etch silicone keypad are always used in instruments or industrial machinery.

However, many clients who want to customize silicone rubber keypads are not familiar with this process. Besides, many silicone products manufacturers haven't professional core technology team. These all caused that the keypad sent to clients without professional testing before. Now BOHAO electronic will introduce the attentions when testing laser etching silicone keypad to you from a professional perspective.

1.Etching through: etching very deep, result in etching through the covering that should not have been etched

2.Missing graphic: the covering not be etched cleaning

3.Laser etch graphic wrong: etching the wrong graphic

4.Dark graphic: the graphic is not clearing

5.Laser etch graphic wrong: the graphic is not the same as sample

6.Shift graphic: the graphic is out of position

7.Burn: the graphic is black

8.Lightleak graphic: using the light box to check, illumination intensity: 600-800lux, light leak somewhere outside the graphic

Leave message